To meet this need, HST has developed a basic/system construction kit for the in-house production of individual engineering products and series products. This design and manufacturing concept allows an optimal coordination of the individual work processes. From the first drawing lines, through work preparation, component manufacture, assembly, right up to systematic functional testing and acceptance at the customer’s premises, every single step is controlled, monitored and consistently documented with the aid of intelligent monitoring systems.

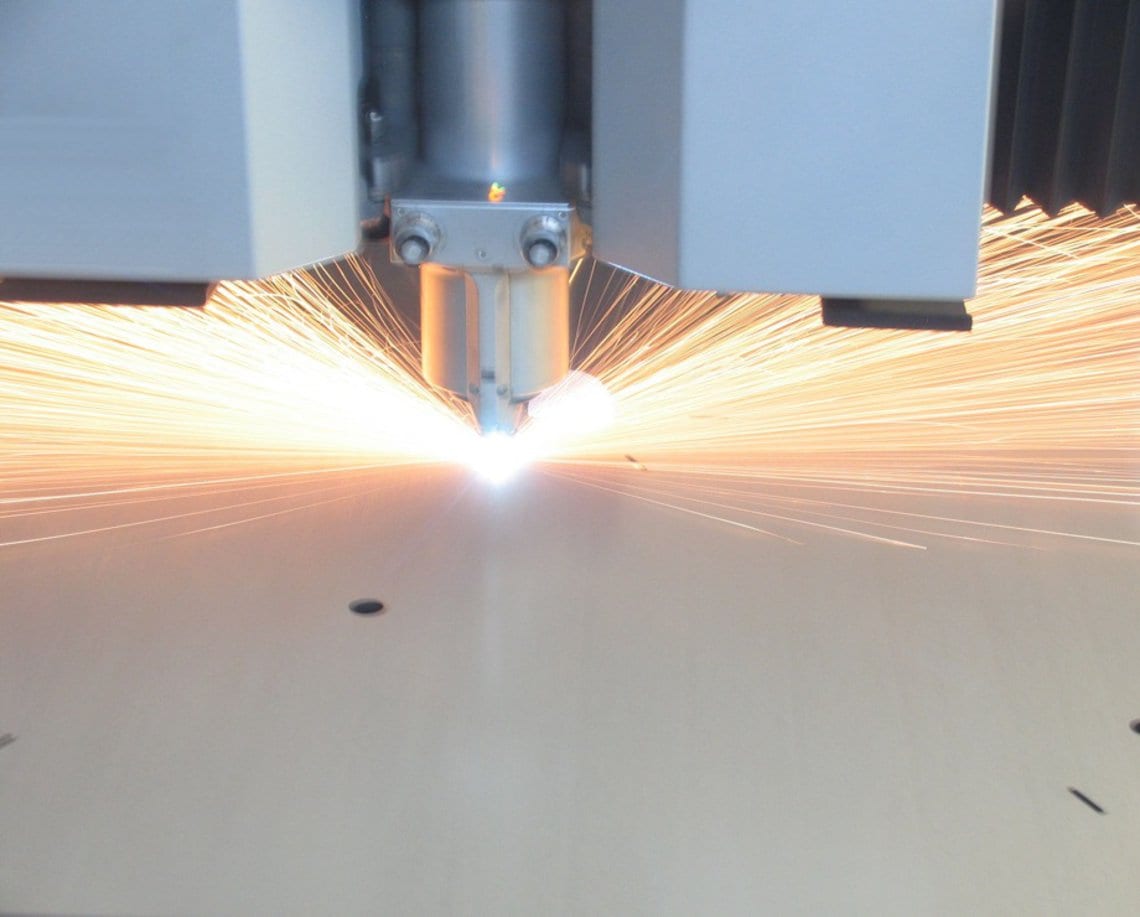

By outsourcing standardized preliminary work to long-standing and qualified partners, it is ensured that the latest production methods are used for each production step and thus meet HST’s quality requirements.

The result is an efficient use of resources in all areas as well as a consistent quality standard at the highest level for all products manufactured in Ramsbeck and Meschede.

In order to implement this concept, HST has invested significantly in its own production facilities for machines and plants in Ramsbeck near Meschede and in the production of EMSR technology on the new premises in Meschede.