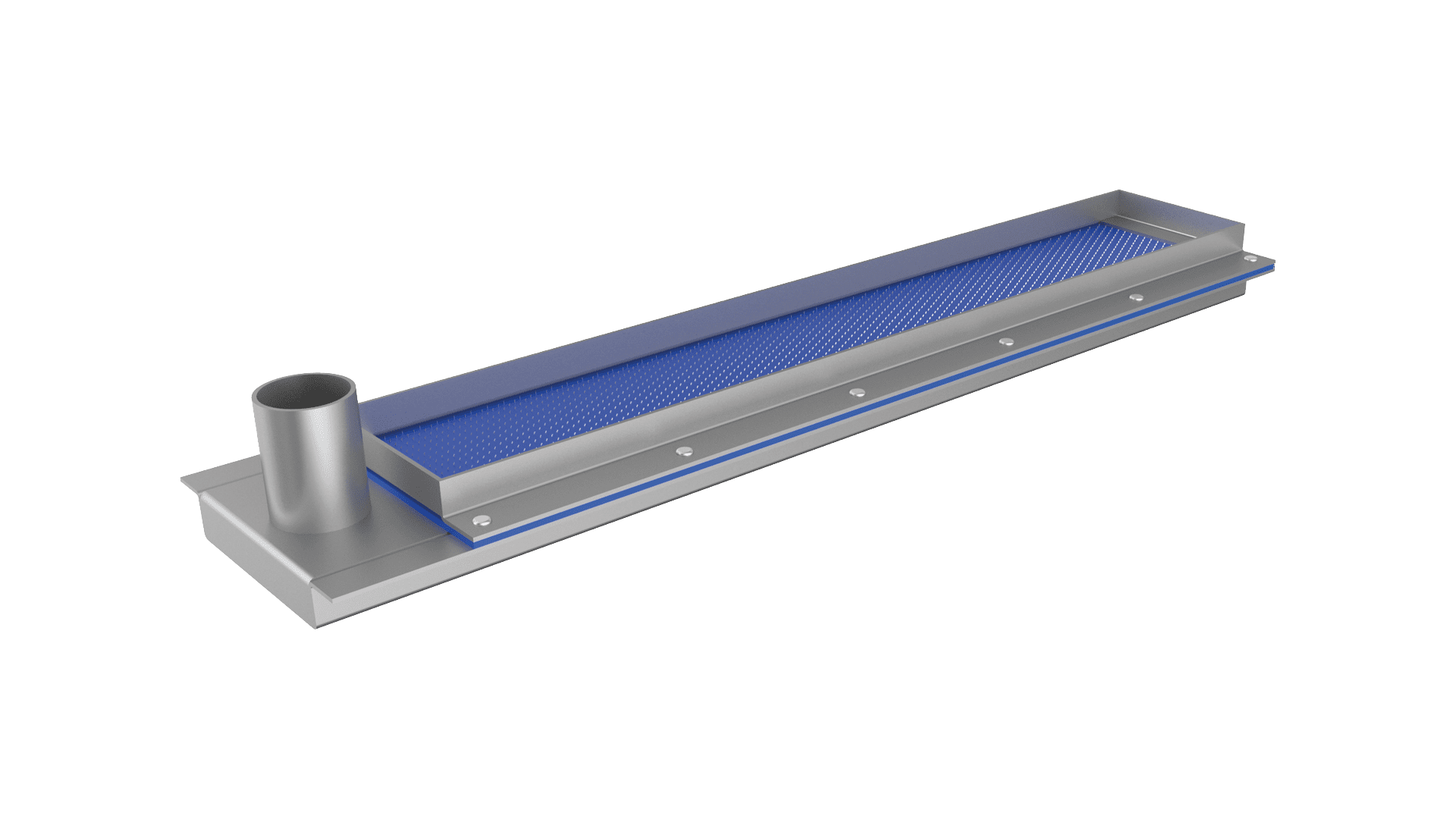

Nozzle Aerator

Product Description

The nozzle aerator is a development for the oxygen supply in aeration tanks. By using this system, energy savings can be achieved because the usual membrane resistance of the current commonly used aerator is no longer incurred. Design-related advantages is another result of the permantent forced emptying of the nozzle aerator. For cleaning purposes, e.g. by feeding , acetic acid of the nozzle holder is backwashed during operation so that calcification or clogging is permanently avoided.

Through an offset arrangement of nozzle aerators and fluid nozzle carriers, the essential circulation or inoculation of the wastewater can also be implemented in the activated sludge tank. Due to the fluid nozzle carriers, a more even mixing of the pelvic volume with reduced energy consumption can be achieved. The fluid nozzle carriers with project-related Di ≥ 1mm have a similar design and also have permantent forced emptying. Backwashing is realized via connectable hose systems.

Your Benefits

- Optimal operation with high performance

- Lowest operating and maintenance costs

- Low risk of clogging the ventilation needles

- Cleaning possibility by backwashing

Applications

- Municipal and industrial sewage treatment plant

- Process water treatment plants

Download

Questions about the product?

Contact us!

Günter Müller-Czygan

Division Manager Process Engineering

+49 (0) 291-9929-44

guenter.mueller-czygan@hst.de