Equipment Tips for Continuous Basins

Stormwater tanks in the form of continuous basins discharge excess water volumes via a sewage overflows (KÜ) and a basin overflows (BÜ). The overflows are usually designed and built as fixed, overflowing weir barriers. Depending on the amount of inflow mixed water at the overflows, overflow heights are correspondingly set.

When designing the sewage overflows, however, it is imperative to ensure that the maximum surface loading or the desired sedimentation capacity is achieved. To limit the overflowing water volumes at the maximum capacity of the basin, the treatment overflows are often throttled or designed as dimensioned openings. Furthermore, mechanical control devices, in some cases, are provided in the basin to regulate the throttling openings, depending on the overflow height of the basin overflow or the resulting water level.

A reminder from HST to all operators and planners: A more effective and useful solution still exists!

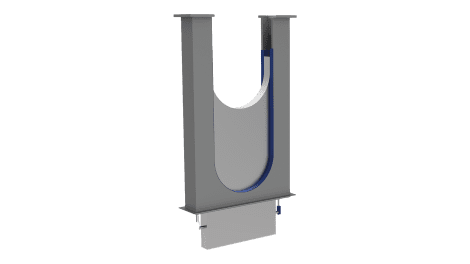

A more effective solution is to equip the basin overflow with a device for constant retention targets in the form of automatic weirs such as the ASK weir.

Equipment of the basin overflow with automatic float-controlled flap weirs

By equipping the basin overflow with an automatic float-controlled water level regulator, the following benefits are achieved:

- Bypassing the throttle / control of the sewage overflow

- Enabling additional storage volume / possibility to reduce the overall cubature of the construction

- Increasing flood and backwater protection

By equipping the basin overflow with a device for constant reservoir target like self-acting weirs, the excess water in the basin overflows are reduced and discharged by a water level-controlled overflow opening. The throttle or regulation of the treatment overflow is no longer necessary and additional storage volume can be used.

The additionally obtained storage volume results from the open basin surface multiplied by the overflow height of the basin overflow at the conventional weir gates.

Due to the omission of an overflow height at the basin overflow or the constant retention level independent of the basin overflow water volume, it is now possible to design the sewage overflow as a conventional overflow threshold without throttling.

The sewage overflow barrier can thus be positioned under the water level at max QKü of the required overflow height. The sewage overflow is consequently located higher and, as a result, more backwater-proof. This enables a maximum possible overflow height to limit the sewage overflow amount. If the maximum storage level is reached, the ASK weir of the basin overflow opens automatically as far as the discharge of excess water is required.

Automatic flap gates or weirs that react to minimal changes in retention level can be used as automatic retention level regulators. These can maintain backwater levels with a hysteresis of max. 3 cm independent of the amount of water to be discharged at the basin overflow.

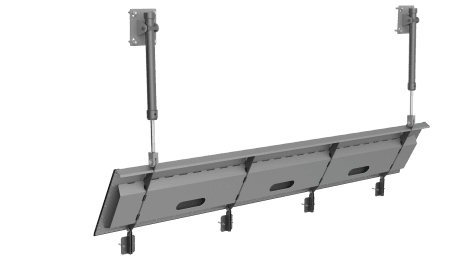

Innovative discharge structures for retention and relief systems

ASA-Weir

ASA weir predominately serve as cascades retention-, flushing- and discharge weirs….

Web Weir-Configurator

The dimensioning and configuration process of conventional fixed weir gates, as well as relief structures for weirs and overflows, has been simplied in HST and can be carried out in a quick and simple manner now! After a few steps you will receive the data for your design with output of the relief flow, overflow height and barriers or flap length. The generated data can be imported into CAD programs to create a system plan in 2D/3D.

CONTACT OUR SERVICE TEAM

Our technical and operational equipment service team will assist you with the planning and execution of all machine and plant services and IT & Automation.

Send us your inquiry and we will suggest a solution.

Tel: +49 291 9929 0

Fax: +49 291 7691

E-Mail: planerservice@hst.de

SERVICETEAM MASCHINEN & ANLAGEN

Christopher Becker

Head of Product Management

Tel:+49 291 9929 23

Email: Christopher.Becker@hst.de

Julia Kappe

+49 291 9929 12

julia.kappe@hst.de